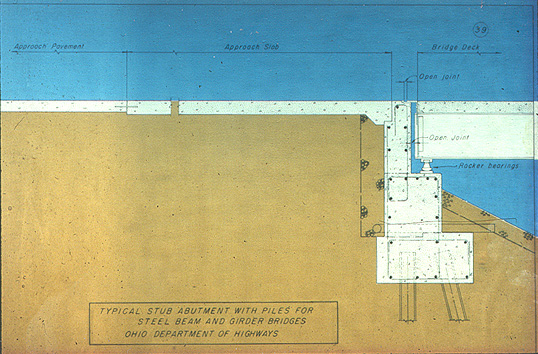

Diagram showing backwall in relation

to abutment and

approach slab.

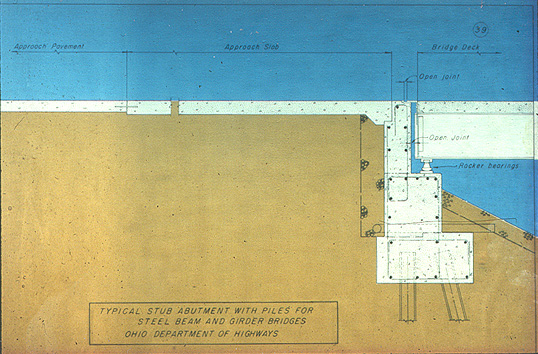

Typical backwall

Typical backwall

BACKWALLS

Backwalls are the vertical walls at the ends of most bridges that extend up from the abutment seats and support the expansion joint. Backwalls are small retaining walls which also support the approach slabs and hold back the embankment under the approach slabs. On bridges with conventional expansion joints, the backwalls also provide the necessary clearance between the ends of the beams and the face of the backwall to allow the bridge to expand and contract.

Diagram showing backwall in relation |

Typical backwall |

Typical backwall |

The most common problem associated with backwalls occurs when the backwall gets pushed into the ends of the beams due to pavement pressure (or pavement growth). This most commonly occurs on bridges that are on highways constructed of several miles of concrete pavement. The concrete approach pavement expands in the summer months, but then in the winter, the pavement contracts. As the pavement contracts, the joints between the pavement slabs open up and dirt, sand, and other incompressibles get into the open joints. As the pavement starts to expand again the following summer, the process continues and the net length of the pavement keeps growing. This pavement growth exerts tremendous pressure on bridge backwalls (which are the weakest link in the growth process), and eventually the backwalls fracture and come to rest up against the beam ends. This then restricts the normal expansion and contraction of the bridge which can lead to several structural problems. This process can be stopped with the installation of pavement relief joints in the pavement just beyond the approach slabs. These consist of asphalt-filled gaps (1 to 2 feet wide) in the pavement. Then as the concrete pavement expands, the pressure is absorbed by the asphalt in the relief joints.

Another typical problem with backwalls occurs on bridges with traditional sliding plate expansion joints, which can leak salt water down onto the face of the backwalls. If the bridge was constructed prior to 1976, chances are that the reinforcing steel is uncoated (or black). The corrosion process begins quickly and the concrete delaminates and spalls off the face of the backwalls. This eventually leads to complete destruction of the backwall. This can be minimized by flushing the face of the backwall and sealing the surface of the concrete.

Preventive Maintenance Recommendations: